If we ever want to live in space, we need to work out a way of creating artificial gravity.

Without gravity, people’s muscles atrophy and their bones weaken. Astronauts develop eye problems and anemia, get blood clots and have to exercise a few hours each day to overcome weightlessness’s effects on the body. Many experience space-motion sickness.

Animals living at very low or zero gravity develop osteoporosis, problems with their eyes and kidneys, and reproductive issues. In 1962, NASA had viable designs for rotating wheel space stations that could have given astronauts artificial gravity. The Apollo program effectively killed this path. While NASA’s lunar focus delivered its moonshot, it abandoned other promising work. Had NASA maintained its parallel pursuit of artificial gravity, we might now have permanent orbital settlements supporting deep space missions rather than the limited, temporarily occupied outposts we’ve settled for.

Subscribe for $100 to receive six beautiful issues per year.

This historical pivot point matters today as commercial space companies contemplate artificial gravity once more. In doing so, they could correct this detour in humanity’s path to becoming a spacefaring civilization.

Wernher von Braun and the von Braun wheel

Early space visionaries, from Konstantin Tsiolkovsky to Wernher von Braun, strongly believed that settling the solar system would need technologies to generate artificial gravity within orbiting habitats.

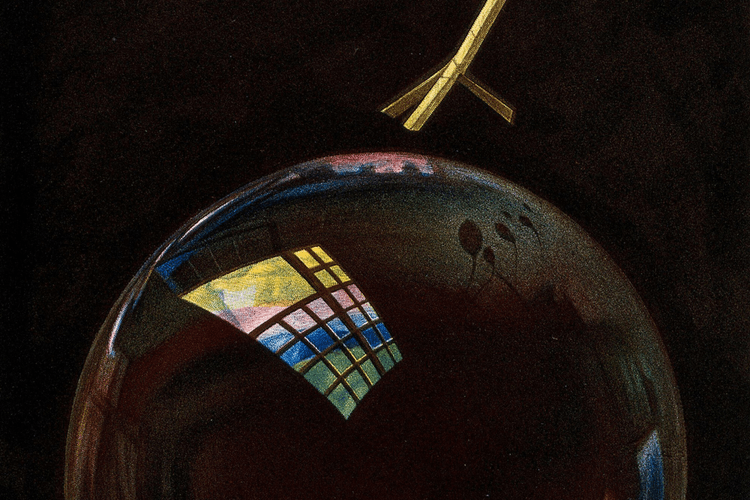

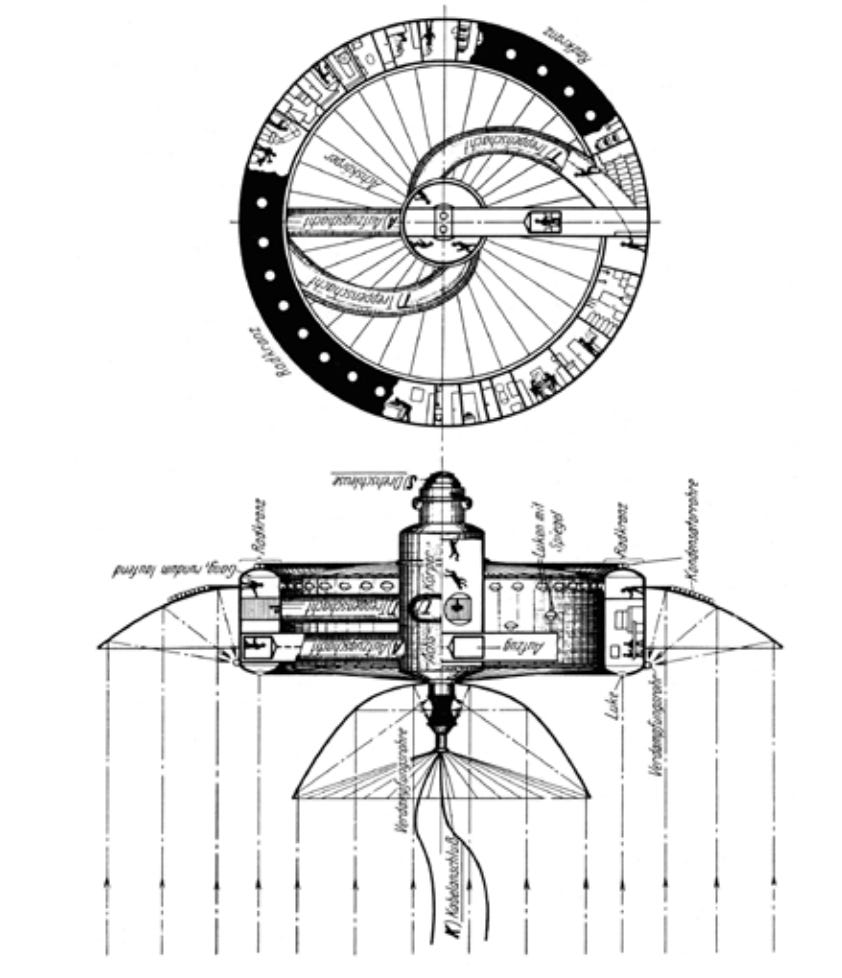

Von Braun was convinced that rotating wheel space stations would be needed to prevent physiological problems associated with space and were thus ‘as inevitable as the rising sun’. In these systems, humans would live in the rim of a wheel where its spin induces perceived weight. While the idea was popularized by von Braun in his 1949 sci-fi novel, Project Mars, the concept actually traces back to Herman Potočnik‘s 1929 book The Problem of Space Travel.

The difficulty of building large stations

This elegant solution comes with a major engineering challenge. Much like a ferris wheel, the rotation of a space station wheel could disorient astronauts if spun too fast. If the wheel spins slowly, then physics dictates it must be quite large – the force pushing you down, which acts like gravity, is stronger the further you are from the central point of rotation. One of von Braun’s designs called for a massive 75-meter-diameter wheel – three times the wingspan of a Space Shuttle – that would generate lunar gravity if spun at three revolutions per minute or Earth like gravity at five revolutions per minute, a speed considered reasonable for astronauts.

However, the physics of rockets presents a competing obstacle: they must be slender, like an arrow, to escape Earth’s gravity well and reach orbit. The challenge is fitting enormous space structures into slender rockets. SpaceX’s Starship is the largest rocket ever launched into space, and yet even its upper stage, which is about 9 meters wide and 22 meters tall, could fit only about a sixth of von Braun’s conceptual station.

The architects of the International Space Station (ISS), the largest space structure ever built, tackled this packing problem by flying up habitable modules in parts and assembling them in space. Such in-space assembly involves spacecraft either gently crashing into each other at specific connection points (a maneuver called rendezvous and docking) or astronauts using space cranes to catch and attach spacecraft to the ISS (known as berthing).

While this ‘space Ikea’ assembly method has been effective, it puts a ceiling on our ambitions. Assembling the ISS meant launching more than 40 rockets over several years (plus even more launches for cargo resupply and repairs). Even with all these launches, the resultant space station is so small that it can support a typical crew of only seven, a little over twice what the first ever space station, Salyut 1, managed in 1972.

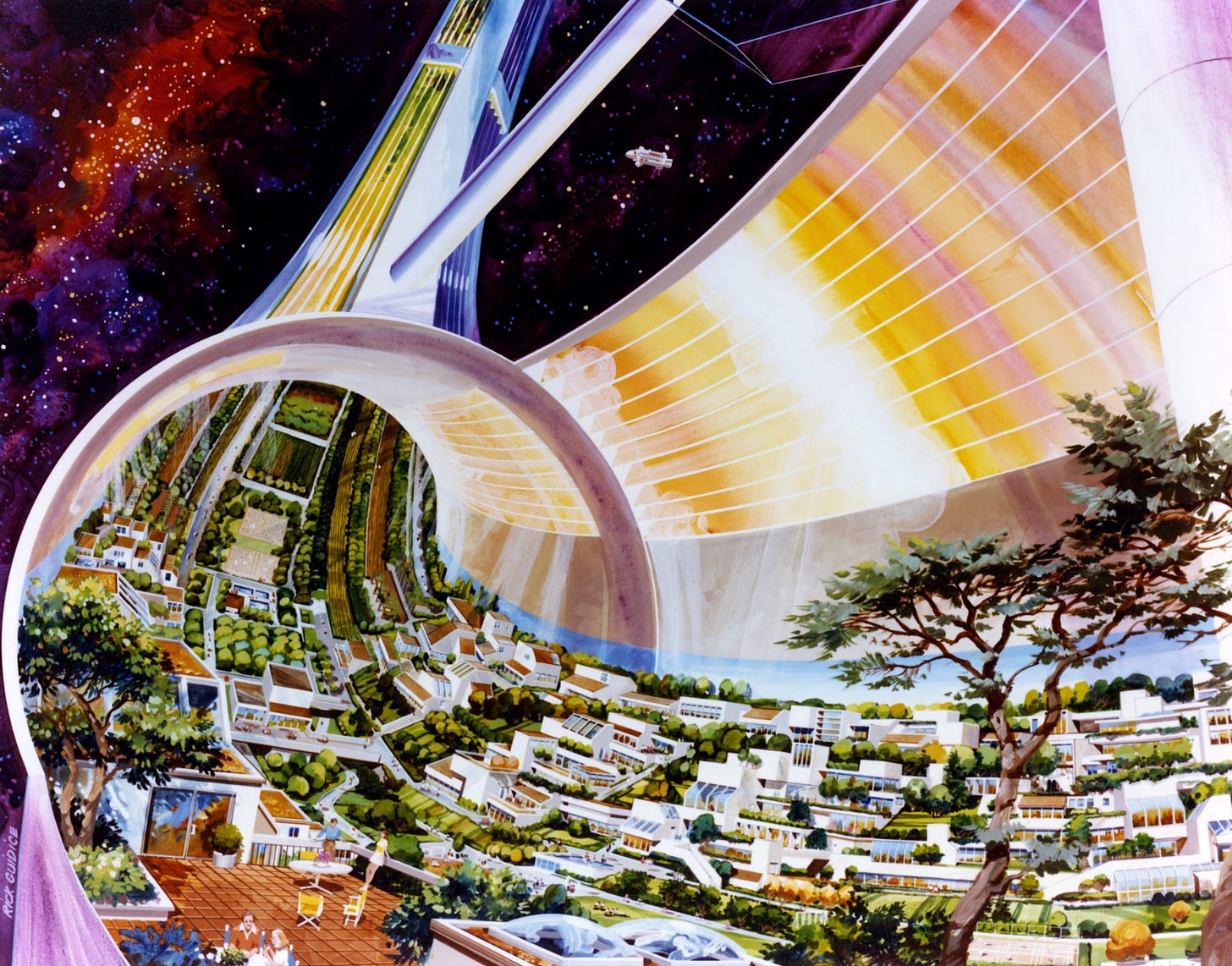

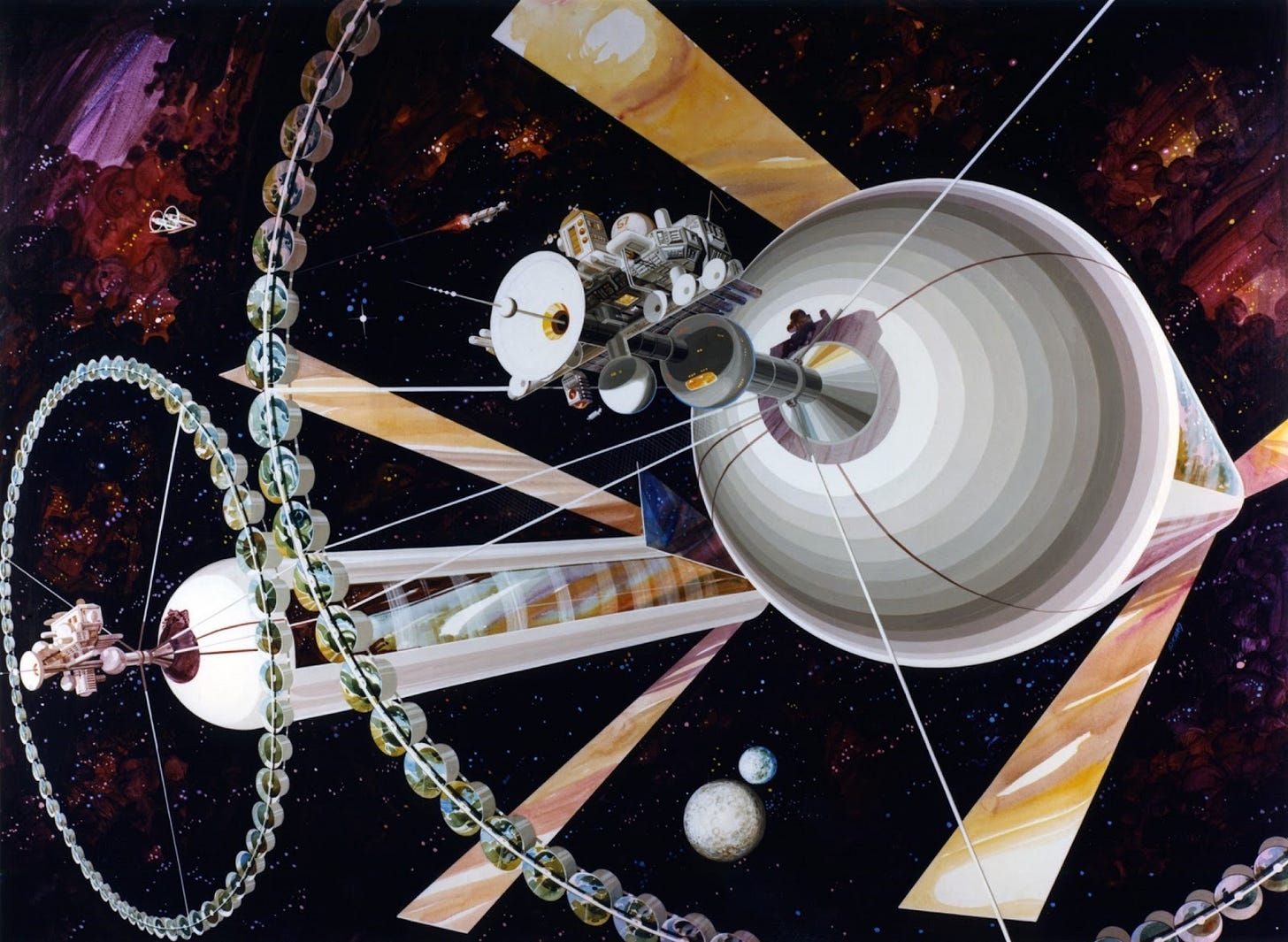

Even with the huge cost reductions in delivering payloads into space made by SpaceX, the sheer scale of materials needed for one of these structures makes it hard to imagine that modular in-orbit assembly will scale to von Braun’s anticipated 80 humans or the 100 people that SpaceX’s Starship is intended to hold any time soon. Civilization-scale megastructures like the Stanford Torus and O’Neill cylinders, which might hold tens of thousands to millions of people, appear even more outlandish today than when they were first proposed half a century ago.

The bottleneck is using small ‘tin can’ modular spacecraft as the centrepiece for assembly. There is a viable alternative, but to find it we need to look to pre-Apollo space technology.

Unitized Stations

Between 1959 and 1962, NASA Langley explored architectures that progressed towards von Braun’s vision of a large space station, without the constraints imposed by modular construction.

A 1959 conference instigated by Larry Loftin, Director of Aeronautical Research at NASA Langley, came up with two prototypes for ‘unitized’ structures, structures that eliminated or reduced the need for in-orbit assembly.

The first idea explored inflating large Goodyear tire tubes into wheel-shaped space stations. Made from soft materials like rubber and nylon, the Langley team was concerned that these tires would be vulnerable to collisions with micrometeorites hurtling through space that could puncture the station, with fatal outcomes.

The second idea came from North American Aviation, which proposed a series of (mostly) rigid hexagonal space stations. This resulted in a 15-foot prototype, made from six rigid hinge-connected pipes. This design folded neatly into a rocket for launch, deploying automatically once in orbit. The rigidity of its habitable elements offered better protection against micrometeorite collisions than Goodyear’s rubber donut. Another three inflatable pipes connected the outer habitat ring to a central hub via air-lock doors, which could be sealed in case of rupture.

These studies also estimated that either system could be realized for $100 million (approximately a billion dollars in 2025). Over time, the hexagonal station emerged as the most promising concept within Langley’s Manned Space Laboratory Research Group, where space station R&D was one of the most active focus areas.

The Apollo Applications Program

The Apollo Program would change everything. In May 1961, President Kennedy’s landmark speech committed America to a lunar landing instead of the original plan to merely orbit the Moon. The Langley team’s vision of artificial gravity space stations was sidelined by Apollo program priorities, which shifted budgets and administrative focus away from other projects, including space stations.

By 1963, the grand rotating hexagon designed for 36 crew members was replaced by the more modest Manned Orbiting Research Laboratory program – a zero gravity facility for a crew of four focused on conducting basic biomedical and engineering experiments. Threatened by cuts, Langley’s leadership managed to keep the project alive into 1965 only through persistent lobbying, which positioned larger stations as the next logical step after Apollo.

This project would go on to become part of George Mueller’s Apollo Applications Program Office. Mueller, NASA’s Associate Administrator and head of the Office of Manned Space Flight, was both a champion of space stations and a shrewd leader. He had a background in military missile testing, and had accelerated the development of the Saturn V rocket with the ‘all-up testing’ method, which involved testing all components of a rocket in a single flight instead of distributed testing over several launches. Thanks to Mueller’s approach, Apollo 8 would orbit the Moon in just the third launch of a Saturn V rocket.

Apollo 8’s premature success could have led to layoffs across von Braun’s Saturn V rocket team. Mueller’s Apollo Applications redirected von Braun’s team to think of life after Apollo, creating an umbrella program that explored multiple new station concepts, including a potential platform for crewed Mars missions, and specialized Earth-orbiting stations for astronomy and meteorology. But NASA Headquarters and the Bureau of Budget would only allocate $300 million ($2.7 billion in 2025 dollars) for follow-on work, instead of the $1.5 billion originally requested, effectively eliminating the possibility of ambitious post Apollo missions.

The competition for Saturn V rockets, which were to launch the lunar missions, further limited station development. NASA Administrator James Webb, having fought to secure funding for 15 Saturn V vehicles to accomplish Apollo’s goals, was initially unwilling to allocate any for space station deployment. Apollo 8’s unexpected early success, however, opened up the possibility of sparing a Saturn V for other uses.

Skylab – America’s first space station – would launch in 1973 on the last ever Saturn V. It fell far short of the grand rotating wheel stations previously imagined: it was a three-person station meant for short stays, built without a dedicated propulsion system. The spacecraft that ferried astronauts to and from Skylab had to provide the orbital boosts necessary to maintain its altitude; it embodied the shrinking visions to come.

After Apollo, NASA dropped the parallelized program strategy, which ran projects like the Apollo Applications Program and Manned Orbiting Research Laboratory alongside the Moon missions. Instead, it adopted a more incremental and sequential approach to space technology development, focusing on the Space Shuttle, and dropping crewed space stations. Meanwhile, the Soviet Union shifted its focus from lunar landings and launched the Salyut program, followed by Mir, conceptually much closer to NASA’s scaled-down Manned Orbiting Research Laboratory than to the ambitious rotating station concepts.

The early visions of large crews living in rotating structures with artificial gravity are now relics of a more optimistic era.

So will I ever get my Von Braun Wheel?

Possibly.

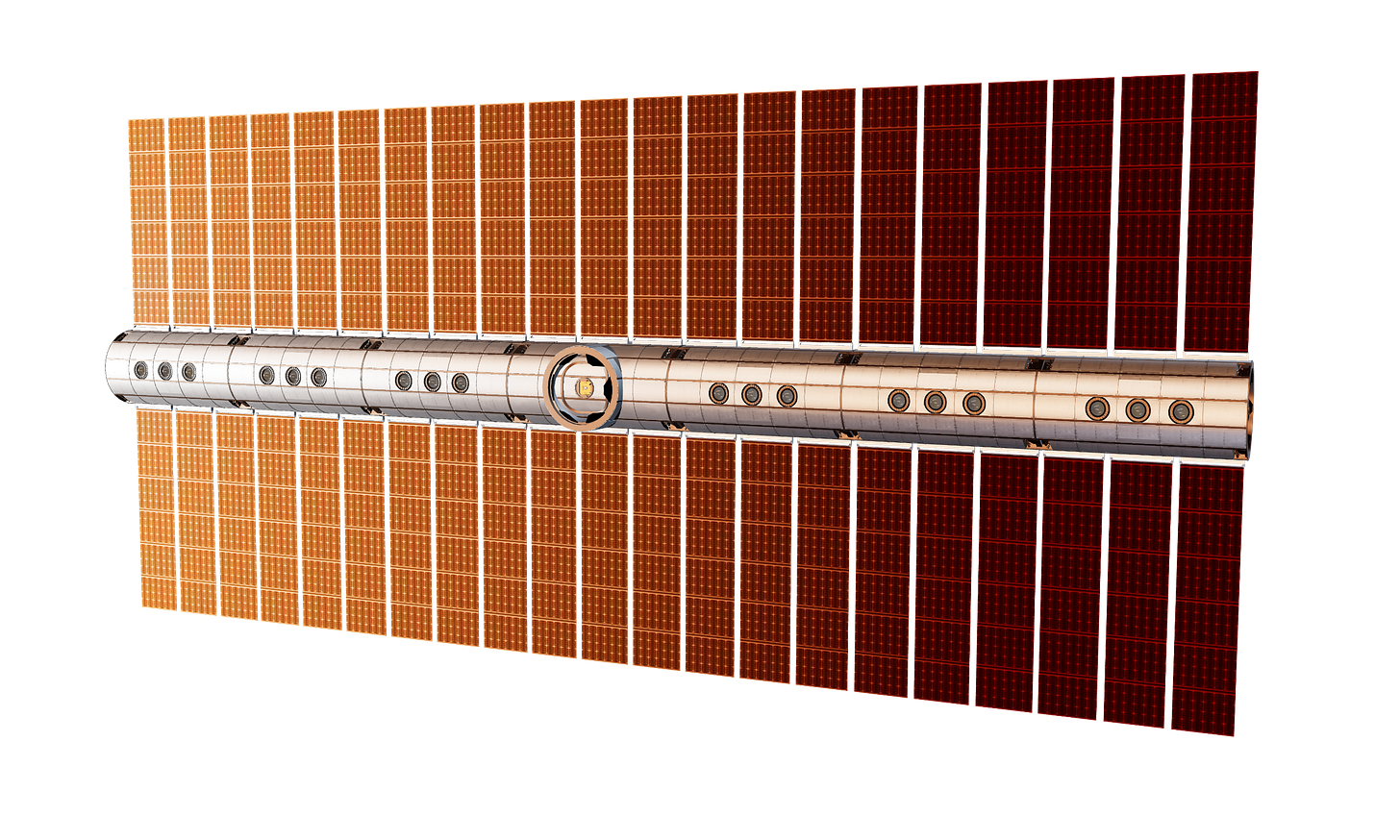

The commercial potential for crewed rotating space stations is gaining attention once again. Vast is one of the faster-moving companies aiming to build one. It is currently developing smaller zero-gravity Haven stations; their 2035 plan is for a 40-person artificial gravity station. Its habitable region is shaped like a long stick which would spin about its center like a two-bladed fan to produce a range of gravities along its length. The limiting feature of its design is that the most desirable higher gravity-zones will only be at the very ends of the stick. This is unlikely to allow its entire crew to enjoy gravity’s perks constantly.

The US government wants NASA to put humans on Mars, giving private space companies a business case for large crewed stations. Almost all space station companies also hope to offer platforms for in-space manufacturing to startups like Varda and Space Forge. Ultra-low gravity just outside the Earth’s atmosphere may produce better pharmaceuticals and semiconductors because this microgravity enables unique crystal growth patterns, prevents convection, and eliminates sedimentation, allowing for purer materials and more uniform structures than possible on Earth.

This focus on manufacturing would remove the immediate need for artificial gravity, potentially making the path to gravity easier by allowing station manufacturers to first focus on rapidly deploying large unitized volumes for uncrewed factories. If Mars does take priority, then a large inflated ring, conceptually similar to the Goodyear tube, could be spun around a rocket to create gravity on journeys to Mars and beyond. Modular designs that build on the ISS’s design cannot be adapted to do this.

Volume is a useful metric for evaluating comfort in zero-gravity stations where astronauts utilize all three spatial dimensions equally. The measurement becomes less relevant for artificial gravity stations, because rotation creates a gravitational force. The ‘up-down’ dimension functions more like it does on Earth, making floor area per astronaut the more meaningful measurement – just as we use square footage rather than cubic volume to assess terrestrial living spaces. Still, larger volumes are a necessary first step toward higher floor space. The problem is that this race for volume makes rigid space stations less and less viable: there is a battle to pack larger volumes as compactly as possible into a rocket.

Volume restrictions are why inflatable stations, like the ones modeled on Goodyear tires proposed early on in the space age, may be ready for a comeback. Volume is a problem they do not face: the difference is like carrying a packed tent in a backpack versus trying to fit a prefabricated modular home into a bag.

The Langley team’s counterintuitive idea to stuff an inflatable tire into a rocket was ingenious, but it was ahead of its time. Without advanced, high-strength fabrics to ensure astronauts’ safety from objects flying through space, the rigid hexagonal station was always going to be the victor.

Fifty years and many advances in materials later, things are changing. The Bigelow Expandable Activity Module, a small inflatable module, was added to the ISS in 2016, based on TransHab, a NASA technology development program from the 1990s. The Bigelow module is made from high strength, but flexible fabrics, including Vectran, and has proven more resistant against colliding micrometeorites and orbital debris than even the metallic modules of the ISS. Bigelow Aerospace, which is now defunct, also claimed the module offered superior thermal management and protection from radiation.

Despite the return to manned space stations, including some with artificial gravity, there is still nothing with the ambition of von Braun’s 6,000-cubic-meter wheel. This is surprising: a wheel built to von Braun’s imagined 75-meter diameter, would require just eight tonnes of compressed air to inflate the structure into its wheel shape, and to maintain an Earth-like atmospheric pressure inside it. That leaves 92 tonnes of usable payload capacity aboard Starship for the structure itself and associated systems.

The actual mass of such a large inflatable habitat is heavily influenced by operating orbit. TransHab was designed to operate in low Earth orbits where orbital debris is abundant. Consequently, about 68 percent of its fabric mass was allocated to shielding against collisions. However, in a low debris environment, shielding mass could be reduced to as low as 14 percent.

If optimized for low debris environments, the fabric-based hull of a 6,650 cubic meter wheel-shaped station, built using the same materials as the Bigelow Expandable Activity Module, could weigh as little as 28 tonnes and pack down to as little as 490 cubic meters (see appendix for calculations). This would fit nicely within Starship’s limits. More conservative assumptions, accounting for low Earth orbit operation with full shielding, yield a structural mass closer to 120 tonnes.

Some engineering challenges remain unresolved, especially regarding the strength and form factor of multi-layer high-strength fabrics used in Bigelow Expandable Activity Module and TransHab. The primary load-bearing component in both cases is Vectran which has only been tested in relatively small cylindrical configurations (up to TransHab’s 8.2 meter width). Whether it can withstand pressure loads in a 75-meter-diameter torus, subject to rotation for artificial gravity, remains unknown.

Starship

Apollo-era NASA was not too dissimilar from today’s SpaceX: beholden to the singular vision of a leader with an arsenal of technical talent capable of executing at speed.

While today’s NASA lacks both vision and investment, it has still engineered multiple successful landings on Mars. NASA’s early Viking landers and the sophisticated Perseverance Rover exemplify the kind of success that other national space agencies can only dream of. The European Space Agency’s Beagle 2 and its joint effort with Russia’s ROSCOSMOS in Schiaparelli both failed to land softly on the Martian surface. Meanwhile, technologists from NASA’s Jet Propulsion Lab pioneered the development of SpaceX’s reusable rockets.

For the first time since the Saturn rockets, we are on the cusp of having a launcher – Starship – that offers the opportunity to make human civilization a spacefaring one. But this future needs artificial gravity space stations.

As impressive as SpaceX’s achievements have been, we should want as many other players as possible pushing progress forward in space. This might mean NASA singularly focusing on rapidly building larger volumes in space, at a scale of funding currently out of reach for companies. It may also require loosening prohibitive regulations, such as the International Traffic in Arms Regulations, which ensure only a select few nations can collaborate on widening our species’ presence in Earth orbit and beyond. It could mean looking to new research models, such as Focused Research Organizations, that have a mandate to focus on developing artificial gravity space station technologies.

So where is my von Braun wheel? Still in 1962. But it could be back, and sooner than 2062 if we want it enough.