Gas heating is bad for the environment. But home-built heat pumps aren’t perfect either.

A friend of mine started working for a natural gas utility a few years ago. The first day on the job, his manager asked him to describe what service the gas company provided.

My friend answered, ‘We sell gas.’

Subscribe for $100 to receive six beautiful issues per year.

‘No’, the manager shook his head. ‘We keep our customers warm and put food on the table for workers.’

That reply is critical to remember right now, because natural gas is in trouble. If gas leaks out before it’s combusted, it gets released into the atmosphere as methane, a potent greenhouse gas. Recent atmospheric measurements show that the total leakage from wellhead to stove is more extensive than previously assumed, meaning that natural gas might damage the climate more than coal per energy unit delivered.

Given this climate impact, eight US states have started regulatory gas decarbonisation proceedings. It’s likely others will follow. Each of them is trying to figure out how gas can meet the state’s emission mandates and their looming deadlines. Even if all the gas leaks were fixed, widespread burning of the fossil fuel itself will need to be banned if the state wants to meet its emission mandates.

So, could this be the end of gas utilities? Will they follow the coal industry in its slow and painful decline? Or can they innovate and deliver their services with a low- to non-emitting product? After all, their customers still need warmth and their workers still need food on the table.

Innovation in the gas business

In the late 19th century, gas was sold by private companies, called ‘gas works’, to light streets and homes. Pipes were sometimes made from repurposed Civil War rifle barrels that were fitted one inside of the other and snaked around underground in urban areas, with the gas varying widely in energy density and chemical impurities. Gas was made back then by cooking it at such a high heat with steam that it created ‘coal gas’.

However, by the early 1900s, Edison’s light bulb began to outcompete gas lamps. Electric lighting was cheaper, safer, and didn’t make the ceiling sooty. So gas companies, now beginning to be regulated as utilities, turned to heating homes and businesses. Heating with gas, rather than coal or wood, quickly became popular because then you didn’t have to schedule regular coal deliveries and have a room devoted to coal in your basement. Thus, this new business proved to be a huge win with a much larger market.

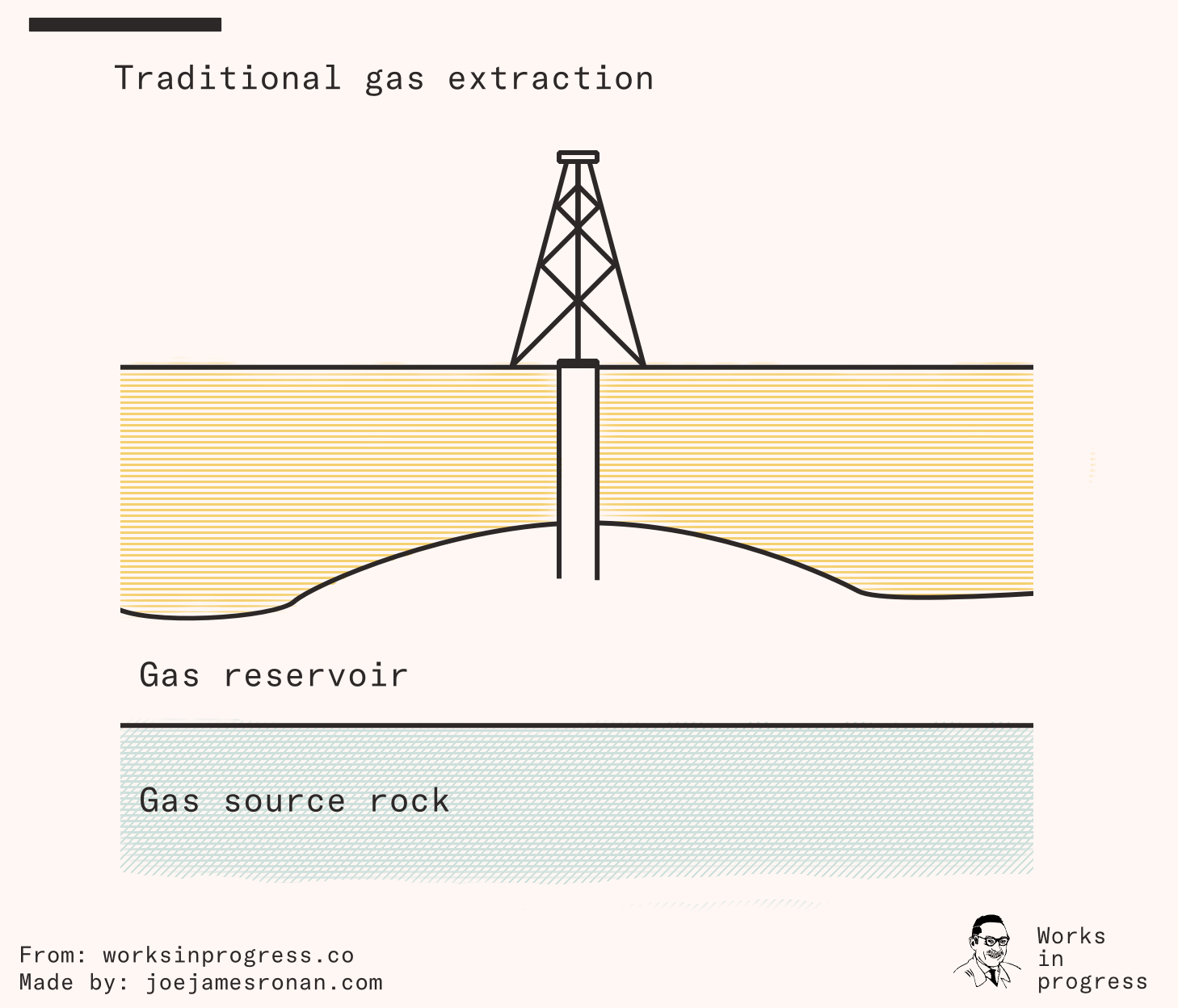

During World War II, vast quantities of coal became critically needed for manufacturing, which made accessing a consistent supply of coal a problem. So gas utilities learned how to mine ‘natural’ gas, drilling down and siphoning off vast bubbles of methane trapped far underground. This gas was less expensive, had a greater energy density, and burned more cleanly than coal gas.

In order to use natural gas, every burner in every coal-gas appliance in every home and business had to be replaced. The scale of this retrofit work was huge. The up-front cost was paid for by the local gas utility and repaid over time through the savings on the lower cost of natural gas. In New York City alone, there were 4.8 million coal-gas ovens, water heaters, and furnaces. Employing an army of workers, in three short years, the local utilities retrofitted all those appliances to use natural gas. This is what utilities can do when their business is at stake.

Current urgency

We need this sort of speed again. The purpose of a utility is to deliver an essential service, one that requires expensive infrastructure, to many customers in a constrained territory. To reduce the monetary impact of that infrastructure, so everyone can afford the infrastructure part of that service, the utility spreads the cost across all customers over long periods of time – often 50 years or more.

This gradual financing means that a utility executive has to plan far into the future, like a maritime pilot steering a cruise ship. If the gas utility has to decarbonise by 2050 and that decarbonisation necessitates installing or changing infrastructure widely in its territory, ideally it would have started this work 20 years ago. If it had started then, all the gas infrastructure could be fully paid for at the normal speed before it was decommissioned, and the renewable infrastructure would not have to be installed in an expensive scramble. Every year that slips by without action means the impact on customers’ bills is likely to be larger.

And bills are important. Currently, for most people across the country, gas is the cheapest way to heat – but even at this low cost, over 21 million gas and electric customers in the States (roughly 16 percent of all households) are in arrears on their bills, unable to pay.

The current preferred method for reducing emissions from heating buildings is to heat with electricity and then produce that electricity with renewables. Heat pumps (a magical technology, as we will see below) are the most efficient way to do that, as they reduce the amount of renewable energy that is needed to begin with, thereby reducing the impacts they have on the electric grid. Thus many states are strongly incentivising electric heat pumps, which are easy to sell since they also provide cooling, improve indoor air (leaving no combustion fumes indoors), and reduce emissions.

But even as gas customers move to electricity, the gas system will remain the same size with the same fixed maintenance costs. Fewer customers sharing those costs means higher gas prices.

The ones choosing heat pumps tend to be the ones who own their homes (renters instead suffer from the famous ‘split incentive problem’ where landlords make decisions about heating systems, while tenants pay the resulting utility bills). In the end, the majority of customers left on the system, attempting to pay the rising costs, will be renters and the low income.

This disaster will also impact the gas workers – the ones in the trucks with the jackhammers. These are some of the few jobs left in the US where a high school graduate can earn livable wages and benefits. Although we urgently need more solar and wind, most renewable-energy workers get paid a fraction of what gas-utility workers earn and don’t get anything close to the same benefits. This gap in wages and benefits is why gas workers fight renewable energy tooth and nail. They have to, for their families.

Returning to that cruise ship analogy, gas utilities are currently steering for disaster, and on board are a lot of workers and low-income customers. Can the utilities adjust their direction and innovate again, providing heat for their customers at a reasonable cost and food for their workers, while radically lowering or eliminating their emissions by 2050?

Well, what options exist? Let’s start with the ones the gas utilities don’t like.

Air-source heat pumps

Boilers and furnaces create heat through combustion, releasing the chemical energy stored in the fuel, losing a little energy up the chimney. Thus, the most efficient fossil-fuel boiler delivers less than one unit of heat to your radiators or ducts for every one unit of energy it burns.

Air-source heat pumps are so efficient because they don’t actually create heat. Instead, they use a technology similar to what’s in your fridge: they move naturally occuring heat to where you want it using a refrigerant, which is basically a sponge for heat. Allowed to expand, the refrigerant absorbs heat. When compressed, it rejects the heat. Pumping the refrigerant in a circle from inside to outside, you can sponge up heat on one side and squeeze it out on the other.

Depending on the local climate, heat pumps generally deliver an average of two to three units of heat for every unit of energy they use. This ratio can seem magical, since humans are unable to see heat. But with an infrared camera, you can see this. I once walked around with one for a few weeks, seeing temperature-like ghosts all around: dark hazy cold crouched in the shade and psychedelic auras of heat emanating from anything the sun touched. Do that for a few weeks and you’ll understand that of course it’s easier to move the heat a few feet rather than create it through a chemical process.

However, when the air temperature outside is more extreme, such as 0°F or 100°F (-17.78°C to 37.78°C), air-source heat pumps have to work harder to do their job. This is one of the few problems with air-source pumps. When you need them the most, they are least efficient, straining the electric grid. Electric peaks require all the dirtiest and most expensive power plants being activated to supply the excess electricity that is needed. If all of our buildings move to air-source heat pumps, those peaks will become mountains.

Ground-source heat pumps

Ground-source heat pumps are another option. These move water through underground pipes to absorb the temperature of the ground and deliver it to your heat pump. Because the ground below the frost line is always close to the ideal temperature for heat pumps, around 50°F to 60°F (10°C to 16°C), the heat pump requires little energy, working at maximum efficiency, even on days when the air temperature above is brutal. This improved efficiency means the impact on the electric grid is roughly cut in half in comparison to a building moving to air-source heat pumps.

However, those underground pipes cost a lot, making the installation of ground-source systems generally at least twice as expensive per building as air-source. And of course, even if every building owner saved up and installed ground-source heat pumps, one building at a time, we’d still have to maintain that gas system until the last customer was off it.

So what other options remain? What ideas are the gas utilities suggesting?

Hydrogen blending

Some gas utilities, like California’s SoCal and the UK’s National Grid, suggest the gas in our pipes today could be blended with hydrogen. There is precedent for this since coal gas (that first type of gas used by gasworks in the nineteenth century) had trace elements of hydrogen. If the blend contained 20 percent or less hydrogen, the gas would still work in our appliances.

The hydrogen could be renewable if it was made using electricity from wind turbines at night, when the demand for electricity is low. In our low-emitting future, this type of ‘green’ hydrogen will be desperately needed for a variety of applications, including ocean-going ships. The question is, do we want it in our pipes?

Currently, green hydrogen costs several times more than gas, and there is essentially none available in the United States, nor will there be in any significant amount for decades, given the electric grid’s hunger for renewable energy. Worse, hydrogen makes pipes more brittle, increasing the potential for older metal pipes to crack catastrophically during frost heaves. And, finally, hydrogen has only a fifth of the caloric energy in it that gas does.

Something that costs more, delivers less, and reduces safety is not a good innovation.

Biogas

Another option is biogas. As food and sewage decompose, they create methane. This can be purified for use in our appliances, since natural gas is over 90 percent methane. Any carbon dioxide made from burning this gas can be loosely considered net zero since the carbon dioxide emitted should be close to the amount of the carbon dioxide sequestered in the growth of the original plant or organism.

However, this net-zero calculation is true only if no molecule of methane, that potent greenhouse gas, leaks out anywhere before being burned. Currently, about 3.3 percent to 4.7 percent of natural gas is estimated to be leaked across the United States. There’s not much reason to believe that percentage will change with biogas.

We are definitely going to need some combustion in the future for industrial processes such as glass smelting. Biogas used on the site where it’s made, to reduce the likelihood of leaks from transmission, is an ideal candidate for that. However, even the most optimistic estimate by the American Gas Association suggests this biogas could by 2030 meet 5 percent of our current use nationwide. And according to a literature survey by Applied Economics Clinic, biogas in Massachusetts would cost between two and eight times more than natural gas. Biogas is caviar. You don’t throw it into your cafeteria-sized container of Hamburger Helper.

Networked heat pumps

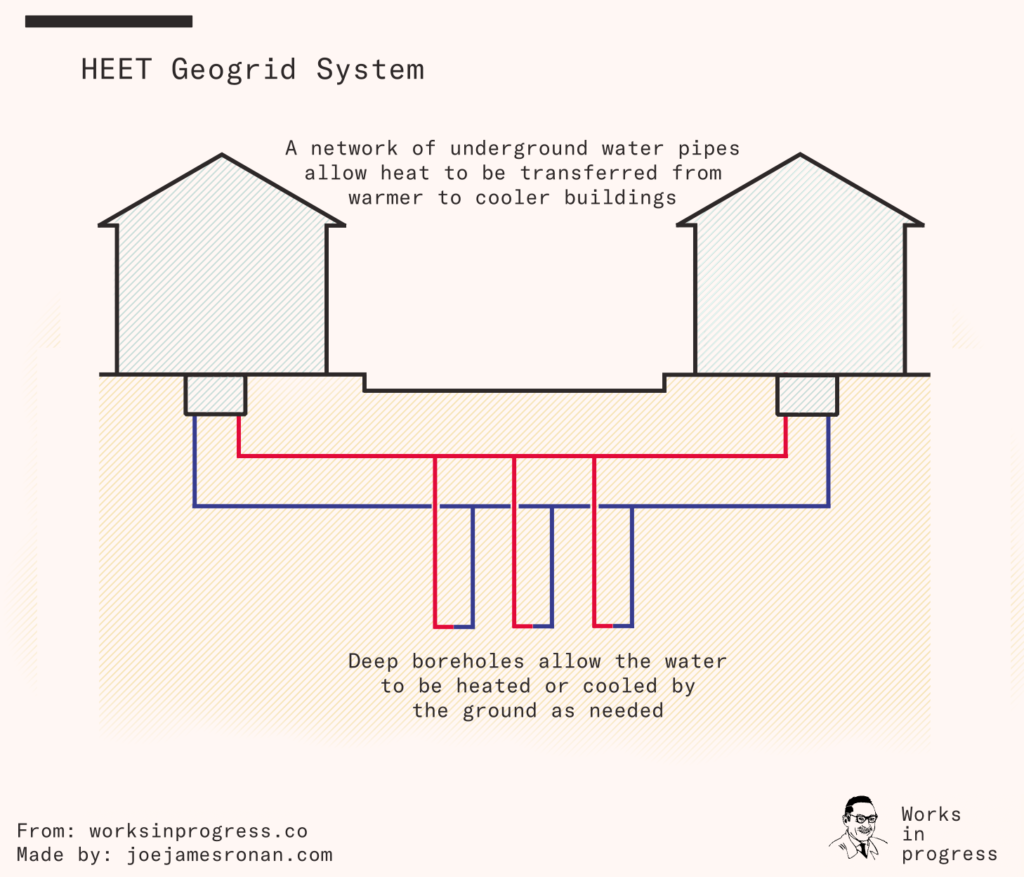

So, what remains? Well, a few gas utilities are trying an unexpected option: networked ground-source heat pumps, something we’ll call a “GeoNetwork”. Over $30 million worth of demonstration GeoNetworks have been approved for gas utilities in Massachusetts and New York.

The boreholes and pipes for these systems can be installed in the street, replacing existing gas infrastructure. The closed system is filled with water, which is circulated through service lines to the buildings. In the buildings, heat pumps extract the heating or cooling they need from that water.

This type of system is being used increasingly in college campuses. It merges the efficiencies of ground-source heat pumps with a network that can move excess heat to where it’s needed – a hockey rink, for instance, will need a lot of cooling, returning the water hotter for the dorms next door. You can also store temperature in the bedrock – for example, you could store the summer’s heat until you need it in the winter. The system allows gas utilities to sell cooling as well as heating, giving them more consistent income throughout the year. And cooling is a product that, on a warmer planet, we will urgently need.

Networks like this – because of the stable ground temperature, the reuse of excess energy, and the bedrock storage – are thus even more efficient than air-source heat pumps, making networked ground-source heat pumps six to eight times more efficient than electric baseboard heating or any gas boiler on a per-unit basis. This efficiency radically reduces electric peaks and the renewable energy needed to create that electricity. This efficiency can allow the electric grid to transition faster and less expensively.

Two different economic analyses (one by Applied Economics Clinic and one by ethree.com) have shown that, so long as the cost of the GeoNetwork infrastructure is paid for like gas infrastructure is – over decades and across all customers – it’s likely that the customers’ energy bills will be lower than with gas. This makes sense since roughly half your gas bill is the cost of the fuel itself. This GeoNetwork uses no gas, so that part of your bill disappears. Because of its remarkable efficiency, it uses such a tiny amount of electricity for the pumps that it can deliver heating and cooling at a lower price than gas. This point alone is worth pausing on.

At least in the United States, investor-owned gas distribution utilities make no profit on the sale of gas, but instead on capital expenditures, such as installing new pipes. This policy dates back to when gas was considered the clean bridge fuel; encouraging the companies to expand was good. In the case of the GeoNetwork, replacing the gas infrastructure could thus be profitable while still keeping customer energy bills low. Nice.

If the six demonstration installations in Massachusetts and New York show positive results, then the GeoNetwork could scale with some legislative changes. Gas utilities would need to be allowed to sell heating and cooling, and not just gas. Potentially, to decrease the up-front cost to customers, the gas utilities could be allowed to pay for the customers’ heat pumps themselves. That way the cost of the transition would be paid for through the savings of the GeoNetwork’s lower customer bills.

A transition plan?

So, is it possible to cobble these different options together instead, to create a possible transition plan?

Where GeoNetworks are financially viable, they can be grafted onto the end of the gas infrastructure, replacing the gas system, one street segment at a time and interconnecting with one another like Lego blocks. At the junction point with the gas system, a gas heater can be installed to provide supplemental heat for the water in the system in case of an emergency. It’s unlikely this backup heat would be needed. A similar system at Colorado Mesa University has functioned for 12 years without using its backup heater.

This backup could help everyone, from customers to regulators, feel confident the system could deliver heat. It can be considered as a kind of gas ‘binky’ – something that reassures the user, but isn’t really needed. As time passed and customers and utilities got used to the system, the gas binkies would be fewer and further away until the gas remained only in the densest areas. Providing backup supplemental heat when needed, only in the cities, is potentially something that we could rely on biogas or green hydrogen for.

Connecting the systems this way creates a single merged geo/gas system that can reduce emissions and maintain investor confidence in the utilities while keeping customer bills down.

In areas where networked geothermal isn’t financially viable, local buildings could be transitioned from gas to single-building installations of air-source or ground-source heat pumps. For example, an innovative utility in Vermont called Green Mountain Power has a leasing program which erases the up-front costs of air-source heat pumps. And Dandelion, a Google geothermal spin-off, installs ground-source heat pumps for a fixed monthly cost. With regulatory approval, a local ‘thermal’ utility could use either model to tactically transition buildings off of gas.

For industries that require combustion, renewable natural gas and green hydrogen could be produced and used on-site. Since this equipment would be expensive to manufacture and maintain, requiring some specialized expertise, it’s possible the equipment and maintenance could be provided by gas utilities. This again would need regulatory or legislative approval.

With thresholds based on data from local underground conditions, infrastructure needs, and energy demand, it would be easy to map out which streets and buildings should move to which solution. With that, we can create a tactical transition plan that would cost the least money and time.

These thresholds will allow the gas utilities to plan out the next few decades, steering the ship to reach safe harbor. The gas utilities could then start the work, putting food on the table for the army of workers they would employ, and providing heating and cooling for all of us.