Libraries contain books, yes. But they also contain latex rubber, carbon fiber fabrics, and graphene aerogel. And in some materials libraries you can cut, cast, drill, sand, scrape, and sculpt too.

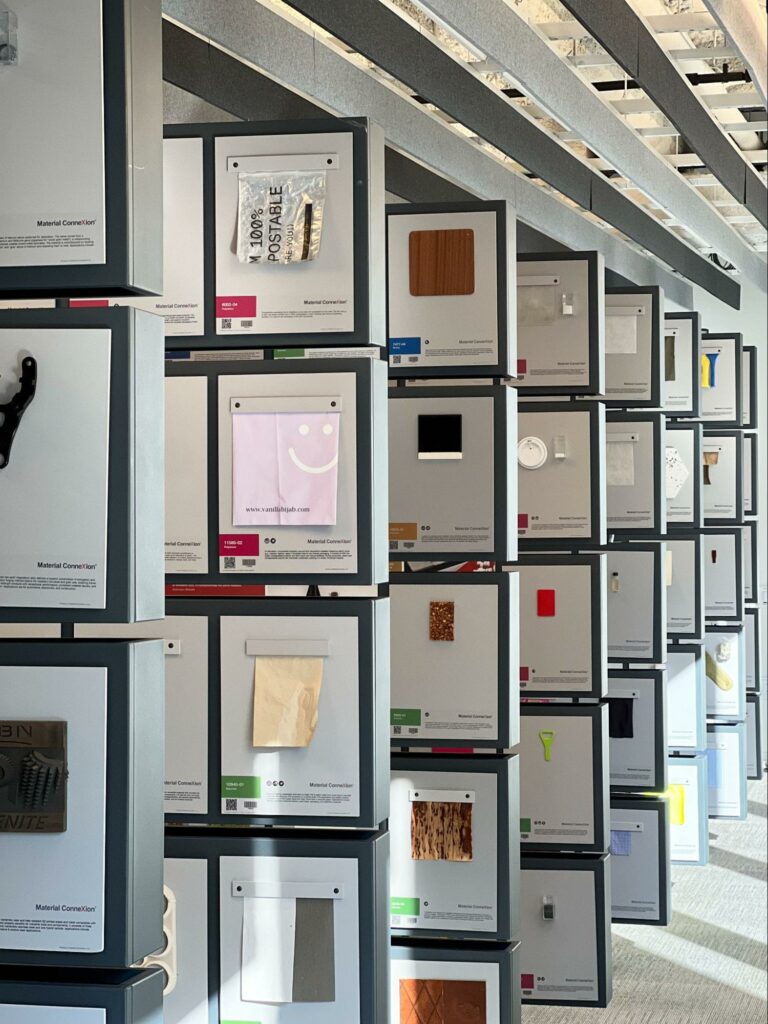

Browsing the aisles at Material Connexion’s Manhattan headquarters can be overwhelming. The displays hold plaques exhibiting a seemingly random assortment of items: a perfume bottle, a shiny black grille, a square of denim, a vial of milky liquid, a scaly swatch of leather, a metal sphere. There are a couple of zippers and at least two toothpaste tubes, plus flooring samples, textile swatches, wall coverings, and assorted containers of mysterious liquids, chips, and powders.

What matters here is not each object itself but what it’s made of. The bottle is demonstrating a premium recycled glass, absent the common greenish tinge. The grille uses carbon fiber oriented vertically along the Z-axis, like the plush threads in velvet. The denim is polypropylene modified to make it dyeable. The vial contains latex rubber from the guayule plant. The leather derives from skins discarded by artisanal seafood cooperatives in Honduras. The sphere claims to be the first high-temperature dissolvable metal alloy suitable for the oil and gas industry. Who knew that fracking requires dissolvable parts?

Subscribe for $100 to receive six beautiful issues per year.

This is a materials library – the world’s first, outside of small sample collections at architecture and design practices. Material Connexion was the brainchild of George Beylerian, a design enthusiast and serial entrepreneur. In 1990, he cocurated an exhibition at the Cooper Hewitt design museum called Mondo Materialis, inviting more than 100 architects and designers to showcase materials they were excited about. The exhibit served as what The New York Times called ‘a coming-out party for such materials as neoprene sheeting and electrochromic glass that could change color throughout the day’.

It also gave Beylerian a vision for a new venture. He would create a place where people could browse, handle, and borrow stimulating materials, a place where playing with material could spark new ideas and make unexpected connections. It would offer an organized and curated collection, independent from suppliers. It wouldn’t sell or broker anything, merely make commercial materials available. Patrons would pay membership dues for access. In 1997, Beylerian opened Material Connexion, calling it a ‘petting zoo for materials’. Along with the expected interiors-oriented crowd, early members included Mattel and Victoria’s Secret. ‘We liked the idea of opening the boundaries’, Beylerian recalled in a 2010 speech. Today Material Connexion encompasses some 10,000 items, with about 1,500 on display in its New York office and more in branches around the world.

Over the years, Beylerian’s vision spread. Universities, art schools, and other institutions established their own materials libraries, sometimes drawing on Material Connexion to help build their collections. The more the world went digital, the more popular materials collections became. Although most provide online databases, their core attractions can’t be reduced to words or pixels. To be understood, materials need to be experienced. ‘The samples are meant to be touched, hefted, inspected, and compared’, urges the website for Princeton University’s architecture and engineering materials collection, which opened in 2017. ‘Please come to the libraries and experience the samples in person!’

Like the open-stack libraries that first emerged in the eighteenth century, allowing members to freely browse the shelves, materials libraries grow out of intellectual enthusiasm. They represent new ways of communicating and organizing knowledge. They remind visitors that we live in a world of fascinating, mysterious, wildly varied stuff. Materials libraries are cool. They’re also practical, spurring individual discovery and cross-disciplinary exchange. Their spread suggests a decentralized way to boost material progress.

For students, materials collections offer the hands-on experience that earlier generations might have grown up with. ‘Undergraduates today are so much more immersed in the digital world’, says Teri Dowling, director of library operations at California College of the Arts, whose materials library includes about 2,500 items. ‘Their educational exposure to physical materials and objects is more limited than it had been in the past.’ Materials libraries and the teaching they support help to fill those gaps.

‘They can touch all this stuff. They can hold it. They are so excited to get their hands on things and be like, “This is made from what? It’s so soft.” It is a really incredible thing to watch,’ says Michael Carroll, who runs the University of Pennsylvania’s materials library. Opened in 2017, Penn’s collection contains more than 9,000 items and is still growing.

Visiting the library gives students a chance to experience materials they’ve only read about in books. Art and art history majors explore samples of pigments and paper. Engineering students fondle ultra-lightweight aerogels. One student squeezed so hard that the aerogel exploded. (The library preserved the broken sample so that students could see the aerogel’s internal structure.) When the Penn Museum of anthropology and archaeology mounted an exhibit of artifacts and garments made from fish leather, the library supplied contemporary samples that visitors could safely feel for themselves. ‘I’m trying to make sure it’s as interdisciplinary as possible’, says Carroll.

Like open stacks of books, materials libraries foster serendipity and surprise. ‘Researchers in a materials collection frequently pick up a material because it looks interesting, or shiny, or bright, or translucent’, wrote materials librarians Rebecca Coleman of the University of Virginia and Mark Pompelia of the Rhode Island School of Design. ‘They dismiss labels that indicate that a sample is marketed as flooring, or insulation, or for erosion control. As they hold, bend or peer through a material, it transforms and inspires – physical contact catalyzes the design process.’ In a world of search, a materials library provides a place for unexpected discovery.

Designer Sandy Chilewich recalls visiting Materials Connexion almost as soon as it opened. ‘It was a candy store’, she says. She came in searching for a fabric for a new type of bowl but instead became intrigued by swatches of woven vinyl used in outdoor furniture. ‘I didn’t even know what I was looking for. But then I knew – I found it,’ says Chilewich. Laying out samples on her table at home, she had an epiphany. She would make high-style, easy-care place mats. She persuaded the factory to weave subtle colors into sophisticated designs. An immediate hit with restaurants, the mats sparked what is now a global business, with a factory in Georgia finishing 40,000 placemats a week. When I told her I have some of her placemats, Chilewich replied, ‘Everyone does’.

More recently, fashion student Olly Shinder was browsing the materials collection at Central Saint Martins, a college of University of the Arts London that is renowned for training design superstars. He spotted a foam he thought would make an interesting garment. Until then, the closest the stuff had been to fashion was the interior of Nike sneakers. When he contacted the foam manufacturer, they were so excited to have their material take a star turn that they invited him to the factory and gave him supplies for free. Shinder used the school’s computer-controlled cutting machine to cut the bright blue foam into what looks like the exoskeleton for a dinosaur-inspired superhero, turning the quotidian material into avant-garde fashion. He called the garment the Serendipity Cape. ‘It was just wild’, says materials librarian Billie Coxhead.

University of the Arts London.

As these examples suggest, most materials libraries emerged from the enthusiasms and demands of designers rather than the concerns of materials scientists. Compared to designers creating fashion accessories, shampoo bottles, or store interiors, scientists working on the cutting edge of materials innovations don’t seem as drawn to fondling stuff.

That paradox puzzled Mark Miodownik, a materials scientist who earned an Oxford PhD with research on turbine jet engine alloys. When he started going to academic conferences he wondered where all the exciting new materials were. ‘I wanted to see this material that switches its state in the middle of the supersonic moment in a rocket’, he remembers. But the cool stuff people were talking about was nowhere to be found. ‘I just couldn’t understand it’, he says. ‘All the people did is talk and show graphs.’

Miodownik started building an eclectic materials collection in his office. Colleagues would drop by to marvel at his latest finds. Materials, he discovered, lure people in, sparking ideas for research and collaboration. Drawing on that insight, in 2005 Miodownik cofounded the materials library at University College London. In 2013, the library became part of the new Institute of Making, which Miodownik directs.

Among the nearly 2,000 items in its collection are sets of tuning forks made from different materials and teaspoons electroplated with different metals, created to test differences in sound and taste. When researchers asked people to rate the sensations of cool, hard, salty, bitter, metallic, strong, sweet, and unpleasant for each spoon, they found correlations with the physical property known as standard electrode potential. In layman’s terms, food will likely taste better on a gold-plated spoon. Going forward, researchers hope that taste data gathered over time might be used to create tools for medical diagnoses.

Housed in the engineering school, the materials library is open to all UCL students and staff and prides itself on appealing to users from diverse disciplines. Visible through large windows from the street, the space feels like a high-end store, with items displayed on lighted glass shelves. Locked display cases protect potentially hazardous or particularly expensive samples, including the spoons and tuning forks. But most of the goodies are out in the open, inviting visitors to handle them.

Beyond a numeral keyed to a directory, nothing is labeled. The library wants to encourage tactile curiosity. ‘This is a research library and not a static display/exhibition’, library head Sarah Wilkes says in an email. ‘Users come to this collection from many different disciplines and with many different research questions in mind, and explanatory labels that categorize materials from one point of view can limit the imagination.’ Besides, says the irrepressible Midownik, ‘It’s much more fun to work them out. The whole point is that they are this interactive delight.’

Against one wall are powders, liquids, and other samples in glass jars – a ‘sweet shop’ of materials – as well as many four-centimeter cubes designed to be handled and compared. (The library owns about 200 such cubes and rotates what’s on display.) Here, the focus is on materiality, not applications. The opposite wall displays larger samples and finished objects, from an alligator handbag to a golf ball bisected to show its interior. Miodownik encourages me to pick up a large, rippled metal ingot. It proves surprisingly light – magnesium. He holds a sample of so-called transparent concrete up to the light, demonstrating its translucence with his free hand. He points me to a mysterious mass imprinted like folded cloth but too solid to be a textile. It’s rubber from Indonesia, whose processing leaves behind the imprint along with a telltale smoky smell. He opens a drawer to reveal an assortment of sponges. ‘These are delights’, he enthuses. His attitude informs the collection. Miodownik loves materials and believes other people will too. All they need is a chance to play with them.

At the back of the UCL library is the Makespace, offering traditional and high-tech tools, from saws and potter’s wheels to 3D scanners and printers. ‘This is your chance to tinker, boil, bake, turn, mill, mend, spin, scan, print, cut, cast, drill, sand, scrape and sculpt’, declares the website. The workshops complement the collection, giving students the deeper understanding that comes from working with materials. ‘When we were first starting and we were only a library, it was a bit frustrating’, says Miodownik. ‘It’s night-and-day different having this access. It makes us not sterile.’

To draw people in and encourage browsing, libraries often curate thematic displays. Visitors to the Penn collection start at a color wall of diverse materials grouped by hue. Among the items in the black section are Vantablack coating, the world’s darkest substance; a swatch of sheer gray organza fabric embellished with a black mesh spiral; and a black-and-gray terrazzo-type slab made from ‘recycled portland cement, fly ash that has been saved from contaminating waterways and rare recycled marble and granite chips from quarries long since closed’.

Central Saint Martins mounts exhibits in the school’s main library. A recent theme was ‘Rethinking Waste’, featuring bricks made from recycled construction waste, a shirt using scraps from the Vivienne Westwood design house, and timber terrazzo composed of waste wood. Some of the paper in the display’s signs is made from old coffee cups. Put together by library assistant Rachel Hollis, the exhibit was inspired when Coxhead realized that ‘most of the things I was sourcing or adding to the collection were made out of some kind of waste’.

Reflecting their users, materials libraries are obsessed with the loosely defined quality known as sustainability. In adding to its collection, Penn emphasizes ‘sustainable, recycled, eco-friendly and healthy materials’, often from niche manufacturers. That focus, Carroll explains, ‘is really the way that we can be most useful, because people can’t go to one single store and find all these sustainable textiles’ or other materials. A faculty member recently visited to see what might be done with sawdust.

So the novel materials that headline many materials collections do not, for the most part, offer higher performance or lower costs. They aren’t stronger, more beautiful, or easier to use. Instead, they promise to reduce environmental spillovers compared to existing options. Material Connexion’s displays include a flooring sample made from rice waste and another using street-sweeping waste, along with a moldable bio-composite made from brewery waste and a veneer made from recycled slate. Their environmental qualities add meaning to these materials, giving them cachet. Hence the artisanal Honduran fish leather.

In these waste-conscious collections, sustainable doesn’t mean enduring. To the contrary, Carroll recalls the time when a student tried to unscrew the lid on a biodegradable water bottle. It fell apart. ‘It’s okay’, he said then. ‘That was purchased in 2018. It’s been five years. It’s supposed to be brittle now.’ He’s excited about the recent acquisition of a polymer monofilament for fishing nets that gets broken down by microbes and cold water within six months. New materials are increasingly designed to disappear.

Even as they highlight ecological concerns, sophisticated materials librarians challenge simple assumptions about what constitutes environmental friendliness. Materials don’t lend themselves to Manichean dichotomies. Consider the carbon fiber nose cone of a Boeing 787 Dreamliner, says Andrew Dent, Material Connexion’s executive vice president for material research. Carbon fiber requires a high-energy process to produce and is impossible to recycle. It sounds like an environmental disaster compared to the infinitely recyclable aluminum it replaces. But its light weight dramatically reduces airline fuel consumption. ‘So not sustainable material – sustainable application’, Dent concludes.

He pushes back against the word sustainable, preferring to focus on specific attributes: ‘Is it to do with a bio-based source of the material? Is it to do with a low carbon footprint? Is it using recycled content? Is it the process using less water? Is it inherently biodegradable in the ocean?’ Implicit in these questions is an unspoken one: what matters to the materials user – the long-term effects on the environment or a symbolic representation of ecological concern?

I find my visit to Material Connexion slightly depressing. There is so much ingenuity on display, in so many different forms, appealing to the eye and the touch. Yet the collection’s emphasis on environmental harms conveys an inescapable sense of melancholy. The library lacks Beylerian’s original joy. Most of this stuff represents guilt-stricken variations on products that existed a half century ago. Guayule rubber was extensively researched during World War II but proved significantly less economical than either traditional latex or synthetic alternatives. Barring genetic improvements, it hardly represents progress.

The last materials revolution was the development of plastics, which took off after Wallace Carothers, who went on to invent nylon, cracked the mystery of polymer chemistry in 1931. ‘Even within the plastic era, it has not necessarily been that we found a whole bunch of new plastics’, observes Dent, who holds a PhD in materials science from Cambridge. ‘What we’ve done is we’ve replaced perhaps dirtier, heavier, harder-to-process plastics with simpler, lighter, much more easy-to-process ones.’

He gives the example of the curvy, cantilevered Panton chair, a classic of mid-century design. Introduced in 1967, the original chair was made of a polyester reinforced with glass fiber. A year later, the manufacturer developed a version in rigid polyurethane foam. Today it’s made of polypropylene, a lighter-weight plastic often used in injection molding. ‘Much easier plastic to process, less expensive and nicer processing, less toxic’, says Dent. ‘Polypropylene existed 50 years ago, but now it’s used in a lot more applications. So there isn’t much new in the world.’ Ours, I conclude, is not a heroic age of materials. The best we can do is exploit the considerable power of recombination and incremental improvement – progress, for sure, but not as exciting as entirely new substances.

Miodownik emphatically disagrees. Real materials progress is happening today, he tells me. The problem is that cutting-edge materials don’t fit easily in a library. Nano materials are too small. Electronics, such as flat-screen displays, require too much power and other support. Biological materials could be dangerous. ‘When we first started, we had lots of people making stuff with cells and biomaterials’, says Miodownik. ‘And then we realized we just can’t control them. Like they could really get bad. And so we had to ban it.’ To realize their potential as spurs to progress, materials libraries need to figure out how to incorporate these challenging categories. The future of materials isn’t all street sweepings and recycled rice husks.

Materials libraries also confront the big question all libraries face: how do you organize the collection? The quality that defines a material to one person may not be relevant to another. A material scientist thinks about molecular structure, a designer about texture, a structural engineer about strength. ‘Students come in and don’t just say, “I need wood”’, says RISD’s Pompelia. ‘They say, “I need something hard” or “something to attach zippers to.”’ Zipper-friendly is an unlikely category.

Classification schemes typically start with broad categories defined by composition. Material Connexion uses eight: metals, polymers, ceramics, glass, cement-based, carbon-based, naturals, and process, which denotes innovations in manufacturing, such as new forms of printing or molding. But substance-oriented classifications alone are inadequate for either searching or browsing. They miss too many of the factors that matter to users, from texture to durability.

So the growth of materials libraries has given rise to a need for new cataloging and database tools. Material Order, a consortium of the libraries at RISD, Penn, Harvard, Columbia, and the University of Michigan, is creating one such system. Each entry includes the item’s composition, use, form, properties, processing, and material ecology, with subdivisions under each. Descriptive text provides additional searchable information. The result is a database that allows someone to easily find, say, sound-absorbing material with recycled content that can be thermoformed or a smooth, abrasion-resistant cloth.

Finally, materials libraries need an Andrew Carnegie, whose philanthropy funded more than 2,500 new public libraries in the English-speaking world. Materials libraries are too rare and too hard to get into. They’re like the subscription libraries of Jane Austen’s day, before the rise of lending libraries open to the general public: a good start but insufficient for widespread materials literacy. Materials Connexion is a for-profit business that charges membership fees. Most academic libraries lack the staff to accommodate outside visitors. A few, including Penn’s, are open to outsiders by appointment. But an intrigued passerby can’t just wander in off the street. Even as a reporter, I got a terse turndown when I first asked to visit UCL and eventually got in only after waiting months.

‘Our events get fully booked in seconds’, boasts the Institute for Making in its annual report. That sounds impressive, but it’s a bug, not a feature: a sign that supply can’t keep up with demand. In the age of abundant digital information, materials libraries offer something scarce: hands-on experience with the stuff that makes the world.